Merchant bars

TRUNINGER magnet systems do not only save space, but also a lot of time! Our magnetic grippers are carefully tailored to your product range, your processes and your crane. This results in fine tuned magnet systems covering transport of complete bundles, loose bars or individual pieces, whatever the task may be.

Applications

Merchant bars are handled mainly in rolling mills and steel plants. In addition, our market-leading magnetic lifting systems are used in steel distribution to pick bars and load them onto trucks, railway wagons, or ships.

Transporting bundles of bars in steel mills

Tough and rugged – steel mill applications

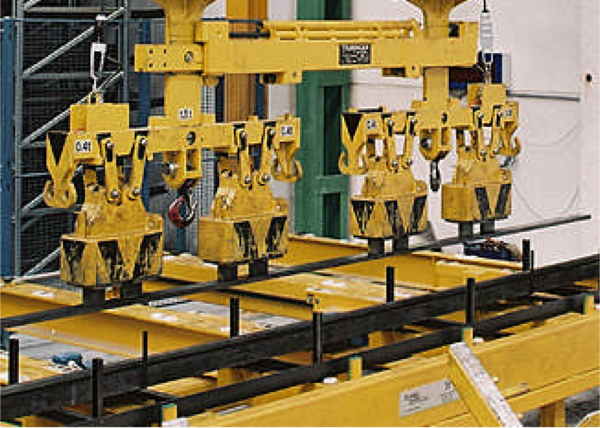

In steel mills, TRUNINGER magnet systems cover a wide range of transport tasks for bars.

Specific features for such applications include robust spreader beam construction and resilient magnet design, also for use on hot material up to 600˚C.

Figure 1: Storing bundles of still hot bars between uprights

Applications

Typical applications are internal handling processes within steel works.

Steel bars in a non-stop production line need to be removed continuously and reliably while shipped out at the end of the line in the dispatch area.

Figure 2: Magnet spreader beam for moving double bar bundles

Advantages of magnet systems

| Your benefits

|

Handling of bar bundles at steel distributors

Faster material handling in the warehouse

A correctly designed magnet system enables fast and safe handling of merchant bars in the warehouse reception as well as storage and dispatch area. You do not only save space, but lots of time as well.

Magnets, when properly guided, allow the load to be approached, picked, unloaded from truck and placed to storage, quickly and reliably.

Figure 1: Unloading bundles of merchant bars from a truck

Such TRUNINGER magnets' poles adapt to the load. Wide pole surfaces are used in the reception area, where larger formats or bundles are typically handled.

Safe transport of material to the storage location

Magnet systems pave the way for denser packing of your warehouse, which results in shorter average crane travel and therefore time saved. Material can be stored efficiently:

- Between uprights

- In stacking cradles

- In cassettes

Storing between uprights

Storing between uprights is a simple concept which ensures maximum stacking height and high storage density.

A perfect field of application for magnets as they require

- No dangerous climbing on high stacks

- No timber spacers between bundles

- No presence of people in material handling zone

- No manual work on sharp-edged material

Figure 2: Placing bundles between uprights

Storage in stacking cradles

Cradle carriers on the magnet spreader beam enable quick loading of bundles into the stacking cradles, mechanical transport of the cradle itself as well as fast order picking of individual bars – and all with the same system. Even a highly diversified warehouse can thus be managed efficiently.

Figure 3: Round bars being carried in stacking cradles

Storage in cassettes

A cassette storage system supports fast, efficient operations within a limited footprint. It enables high levels of flexibility and productivity for handling and picking small to medium quantities and fast-moving products.

For moving material in and out of the cassettes, TRUNINGER offers magnet systems capable to handle both, bundles and single bars as well.

Figure 4: Two round bar bundles being lowered into a storage cassette

TRUNINGER magnets and spreader beams can be used universally in different areas of your warehouse and boost your material flow with high levels of safety and availability.

Customer order picking

Fast, flexible and efficient commissioning

A properly designed magnet system enables fast and reliable material flow from goods reception to storage to dispatch areas. You do not only save space, but lots of time as well.

For moving material in and out of stock, TRUNINGER offers versatile magnet systems capable to handle bundles as well as single bars.

Figure 1: Storing bundles of bars into racks

Such TRUNINGER magnets' poles adapt to the load. Wide pole surfaces are used in the reception area, where larger formats or bundles are typically handled.

Adjustable magnetic grippers

Magnets with variable pole geometry are ideal to feed cutting or machining lines and order picking stations.

Using a retractable anchor system, the magnet poles can be adapted to match the load.

With the anchors extended, individual bars or smaller quantities of material can be picked with ease.

Figure 2: Picking selected quantities according to customer order

Extended anchors also allow quick and easy access to individual bars located in the cassette's corner.

Figure 3: Picking a flat bar using the retractable anchors

Dispatch area

In the dispatch area, highly flexible magnet systems are needed. The enormous number of different steel bar products with various shapes and dimensions, plus a wide variety of customer-specific bundles, requires a versatile magnet system suitable to cover many different handling task.

Figure 4: Customer orders being loaded

TRUNINGER magnets and spreader beams can be used universally in different areas of your warehouse and boost your material flow with high levels of safety and availability.

Features

- Retractable poles simplify transport of bundles and singles

- Cradle carriers allow separation of same products in minimum space

- Swivelling magnets adapt to different load widths

- Finger poles prevent the load from rolling off

- Fine control of magnet lifting force for fast order picking

- Almost complete removal of residual magnetism (< 2mT)