Round bars

Large diameter round bars represent a particular tough challenge for magnetic handling—one that we have been taking on for a long time. Thanks to their deep magnetic field penetration, TRUNINGER lifting magnet systems move even the heaviest steel safely and reliably.

Applications

The main field of application on round steel bars are steel mills and specialized steel trade warehouses. This is where TRUNINGER technology proves its market leadership day by day.

Single round bar transport

Faster, safer and more efficient handling of round bars

A properly designed magnet system allows fast and safe access to stock in the warehouse reception, storage bays and dispatch areas. By using a TRUNINGER magnet system you save not only space, but lots of time as well.

Small to medium diameter bars do require their specific magnet systems. For larger diameter round bars, TRUNINGER supplies tailored magnet systems featuring deep magnetic penetration to enable safe transport of heavy loads. Magnet poles shaped to fit the load contribute to reliable handling.

Figure 1: Handling round bar weighing 16,280 kg

For round bars, not just mild steel is transported but often hard magnetic high grade steel as well. Also here, the material needs to be free of any residual magnetism to avoid interference with the following manufacturing and cutting processes. DDS demagnetisation technology developed by TRUNINGER removes residual magnetism to lowest uncritical levels also in case of demanding hard magnetic materials.

TRUNINGER magnets and spreader beams can be universally used for moving stock in and out of storage and for internal transport, e.g. around a sawing shop. Thanks to high levels of availability they also ensure a constant and safe material flow.

Heavy plate transport in trade

Fast gripping and safe transport to the warehouse

The ability to grip heavy plates from above by means of correctly dimensioned magnets has become an indispensable part of modern material handling. Well guided magnets allow the load to be approached precisely and fast, picked safely, lifted-off the truck and transported in short time to the storage location. With TRUNINGER magnet systems, the lifting force can be controlled stepless so that even thin plates can be separated and quickly distributed to different storage or work zones.

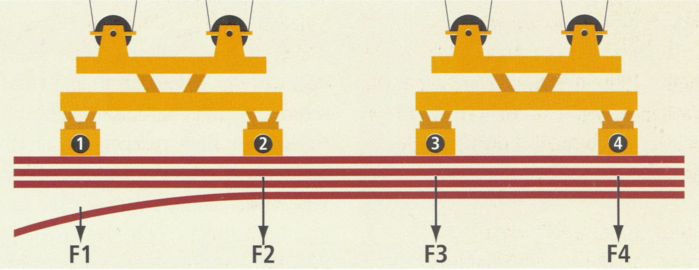

Figure 1: Order picking of plates

The process of separating plates is shown schematically and simplified (see figure 1). For the magnet on the very left (number 1), the lifting force is continuously reduced. Excess plates will thus fall-off piece by piece peeling off from the other magnets. This is an unbeatable advantage compared to transport with mechanical gear.

High stacks – very compact storage

However, fast, reliable and efficient handling of steel plates in the material flow is just one of the benefits offered. Magnet systems also permit more compact storage in your warehouse.

Advantages

| Benefit

|

Plate storage

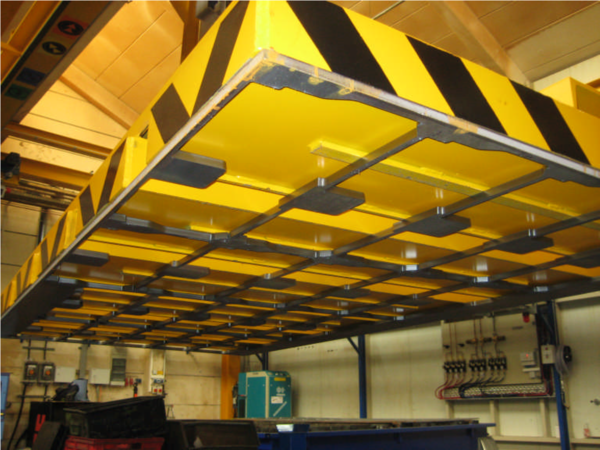

Two spreader beams, each equipped with two magnets (see Figure 2), represent the most efficient solution. The distance between the two independently controllable groups of magnets can be adapted to different plate lengths. Short plates or rest plates can be lifted with one spreader beam only. The foot print of the system is never overlapping the plate, which facilitates placement next to walls, high material stacks or in trucks, railway wagons and ships.

Figure 2: Plate transport using two independent spreaders

The upper spreader beam's load balancing mechanism ensure the load to be evenly distributed among all magnets (see plate deflection in figure 2).

In warehouses where a wide range of different material is handled, a space-saving alternative to horizontal stacks is

Vertical plate storage

Vertical plate storage is an other inspiring development of TRUNINGER. In contrast to horizontal stack storage additional structures are needed for storing the plates vertically. Such structures consist of upright racks densely arranged at a slight angle (see figure 3).

- The plates are stored compactly in racks grade by grade.

- Access to the plates is quick and easy (There is no need for re-stacking).

- An unbeatable benefit in terms of time saved, storage density and related operational costs.

You will find more information on vertical plate storage in the document ‘Vertical plate storage’.

Figure 3: Picking plates out of a vertical plate stock with two independent groups of magnets

Other benefits of TRUNINGER magnet systems

- Access to material from above with no pressure marks or damaged edges

- Picking of individual plates and/or multiple loose plates according to demand

- The entire system can be designed with built-in redundancy, i.e. from magnet controller to power supply line to the magnet itself, the system incorporates redundant components

- Use of different spreader beams with a single magnet controller

- Fast interchange of spreader beams using a TRUNINGER Quick ChangeTM system

Figure 4: Lifting multiple long, thin plates in a compact storage

Loading and clearing cutting machines

Increase Cutting Machine Throughput

Flame cutting machines are becoming increasingly powerful and precise. Fast feeding and efficient clearing of the machine table considerably increase the machine's performance and thus the economic efficiency of the work process. TRUNINGER magnetic systems are specially designed to match these applications.

Figure 1: Removal of a scrap frame from the flame cutting table in one crane cycle.

The use of magnetic systems for loading and unloading flame cutting machines has become established worldwide. The fast, safe and economical use of magnetic grippers goes along with further

Advantages

- High availability of the flame cutting machine

- Removal of flame cut parts and scrap frame in one stroke

- Direct feeding of the plates from store without additional slinging gear

- Removal of unused plate sections using single magnets

- Elimination of heavy physical work

Your benefits

- Significant time savings due to higher handling speed

- Attractive workplace, greater safety, fewer accidents

Optimal solutions on a large and small scale

Magnetic lifting systems nowadays play a central role in shipyards and are in constant operation. The time factor is essential in the construction of large cruise ships. This makes it all the more important to carefully optimise all resources involved such as huge automatic plasma cutting machines. TRUNINGER magnetic systems boost this work process significantly. A special spreader beam with a large number of round magnets feeds the cutting machine with a long plate. After cutting, all cut parts together with the scrap frame are removed from the machine table in one stroke and placed on a dedicated sorting station. The plasma cutting machine starts the next cycle of operation while at the sorting station, cut parts are cleared by means of a further magnet system.

Figure 2: Special spreader beam for placing large plates on a cutting table; cut parts and scrap frame get cleared away in one lift

There are also efficient magnet lifting solutions for smaller cutting machines similar to the application described above (see Figures 1 and 3). Please ask us!

Figure 3: Magnetic lifting of cut-off parts and scrap frame all in one stroke

Features

- Retractable poles simplify transport of bundles and singles

- Cradle carriers allow storage of same products in minimum space

- Swivelling magnets adapt to different load widths

- Finger poles prevent the load from rolling off

- Fine control of magnet lifting force for fast order picking

- Almost complete removal of residual magnetism (< 2mT)