Operator training

Efficient operation by qualified personnel

Efficient operation of the magnet system means:

- Proper usage according to specifications

- High levels of productivity – no downtime

- Safe operation

- Optimum life cycle costs – minimal maintenance and long service life

The best results are achieved when the operators have adequate training and the system is regularly used. Ideally operators should also have several years of experience in using crane and magnet systems.

Figure 1: Operator of a magnet system for beam transport

Training concept

Drawing on the company’s broad experience as a manufacturer, TRUNINGER offers operator training focussed on practical operation of the system. The training normally takes place at the customer premises.

Initial training generally forms part of the system deliverables and is provided following commissioning. Refresher courses or training sessions for new personnel are also conducted on site, and ideally linked with other TRUNINGER services, such as maintenance, maintenance training or inspections.

The areas covered by the training are based on the TRUNINGER User Guide.

Operator training focuses on:

- Safety aspects

- Normal operation

- Fault diagnosis and troubleshooting

On completion of the training operators receive a TRUNINGER certificate confirming their participation.

Maintenance training

Availability and reliability by maintenance

Customers expect high levels of availability and reliable operation from their magnet systems. Breakdowns and interruptions by maintenance need to be kept to an absolute minimum.

All TRUNINGER systems are designed for lowest maintenance. Nevertheless, some preventative maintenance is necessary for ensuring optimal availability and reliable operation as well as guaranteeing a long service life.

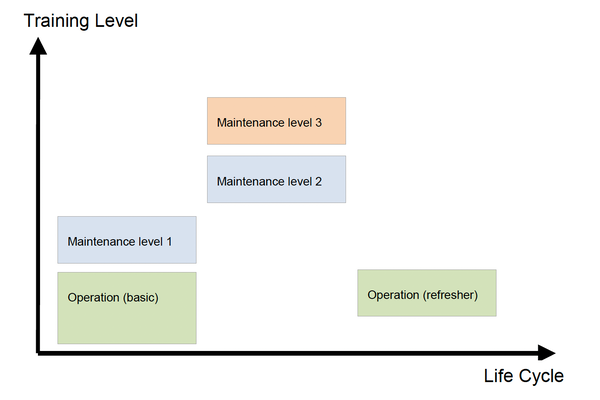

Maintenance levels

TRUNINGER splits maintenance into three levels:

Maintenance level 1 Performed by the operator

Training includes:

- Level 1 safety guidelines

- Cleaning tasks and mandatory system checks

- All of operating functions and detection of malfunctions

- Detection of mechanical damages on spreader beams, magnets, cables or cable reelers

- Read out events on InfoPick

- Any maintenance inside the controller cabinet are subject to higher level 2 training

Maintenance level 2 Performed by trained maintenance staff

Level 2 maintenance training is provided in-house at TRUNINGER and usually lasts 4-5 days.

Training includes:

- Level 2 safety guidelines

- Download the event log via Bluetooth or serial interface

- Track and isolate faults based on the event log

- Replace mechanical or electrical spare parts

- Reboot the magnet system

Maintenance level 3 Performed by TRUNINGER or approved agent

Level 3 maintenance tasks must be performed by TRUNINGER technicians or by TRUNINGER-approved local agents. Level 3 maintenance tasks cover any changes affecting the system specification, functionality or safety.

For example:

- Reworking/replacing magnets or electronic components

- Repairing electrical components

- Changing system configuration or parameters

- Reprogramming or upgrading the main board

- Recommissioning a modified magnet system

Training concept

Drawing on the company’s broad experience as a manufacturer, TRUNINGER provides the opportunity for customer’s staff to be trained for level 1 and level 2 maintenance.

On completion of the training the participants receive a TRUNINGER certificate. The participants are registered in a database to keep track on their qualification.