Billets, slabs and beam blanks

Steel mills, rolling mills, as well as trading companies rely on TRUNINGER lifting magnet technology when transporting billets, slabs, and beam blanks. They ensure the safety of employees, enable fast handling even of hot materials, and feature low life cycle costs.

Applications

Clearing billets or slabs from the cooling bed, loading beam blanks into a pusher furnace: TRUNINGER lifting magnet systems are characterized by low-maintenance robustness which warrants decades of service life even when used on hot material.

Transporting beam bundles in steel mills

A wide range of applications

In the production process of beams and profiles, TRUNINGER magnet systems are used for many different transport tasks.

Transporting layers of hot beam blanks with a temperature of up to 600°C using special heatresistant magnets from TRUNINGER (see figure 1) is one example of such an application

Figure 1: Transporting layers of hot semi-finished beams

At the end of the production, beams and profiles need to be cleared away synch and in time with the manufacturing process.

This often requires the use of magnet lifting systems, because only these achieve the speed necessary to keep up with the continual flow of finished products to be transported to the dispatch storage or lading zone.

Magnet grippers designed for this job are characterized by robust spreader beams and indestructible magnets.

TRUNINGER design features

Different material lengths, nature of bundles or crane type require equally different designs of magnet spreader beams. Components used here include fixed spreader beams with travelling magnets (see figure 2), two individual spreader beams or an active telescope (see figure 3).

Figure 2: Magnet spreader beam used to move beam bundles to the dispatch storage area

The magnets can be moved by motor drive located in the magnet controller - and are therefore positioned correctly on the load matching the respective material length. This minimises load deflection and guarantees safe transport.

Magnets are rotated or moved sideways to adapt bundle or layer width.

Figure 3: Dispatching and loading 3 beam bundles in a single operation

Magnets equipped with variable poles do adapt to contours of different load (see figure 4).

Figure 4: Finger poles automatically adapt to the contours of H profile bundles

Further advantages of lifting magnets

| Your benefits

|

Transport of beam and profile bundles

Quality assurance & safety

Logistics companies are the link between steel mills and steel distribution centres. They deliver products from the producers to the wide spread distributors in high quantities and perfect condition.

Accordingly, the steel products are often transported in bundles or packs. The large number of different products with varying lengths, sizes and weights calls for a lifting system suitable for universal use. It must be able to carry heavy loads safely and guarantee the material’s quality to be preserved.

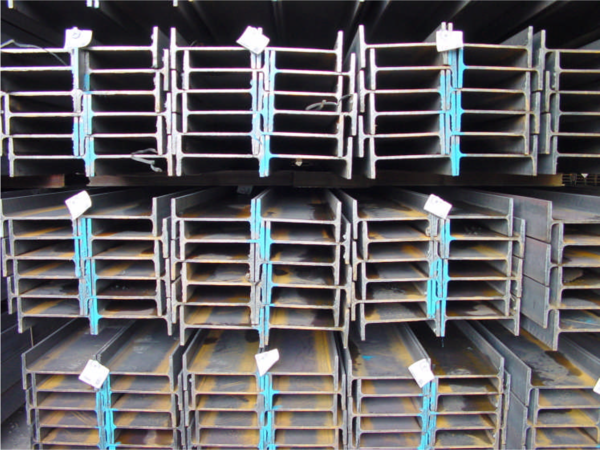

Figure 1: Typical storage of beam bundles

One alternative to using pure mechanical lifting methods, such as belts and chains, is to employ magnet lifting systems.

Magnet systems for beam bundles

Using a magnet system for handling beam bundles and profiles offers the following advantages.

Figure 2: Magnetic transport of H-shape beam bundles

Advantages

| Your benefits

|

Beam bundles up to 24m

TRUNINGER designs and builds special magnet lifting systems for handling all commercial

length of beam and profile bundles.

- The design of the magnet spreader beams is adapted to lengths and nature of the material bundles. Typical solutions are fix length spreader beams with travelling magnets, two independent spreader beams (see figure 3) and, quite frequently, an active telescope (see figure 2).

- The magnet control system enables the magnets to be moved automatically and thus to be positioned on the load correctly matching the respective length. This minimises load sag and guarantees safe material transport.

- Magnets slewing or moving sideways do adapt to different bundle widths.

- Automatic quick change between magnets for bundles and magnets for single beams.

- Magnets featuring deep magnetic fields relieve the strain on the bundle's steel strappings and therefore increase transport safety.

- The magnets are fitted with variable geometry poles that adapt to the shapes of the load being carried (see figure 4).

Figure 3: Two independent spreader beams with quick change system unloading a railway wagon

Figure 4: Finger poles adapt to the shape of an angle bundle

Handling of single beams and profiles

Gaining space cuts costs

Storage space costs money. Therefore, it is most important to make efficient use out of the

available space.

The magnets used in warehouses for beams are particularly slim, allowing to operate even in the narrow gaps between stacked material. Distances between material stacks or even aisles are no more required.

When using magnet systems, wooden spacers are also history. Given a firm foundation, larger beams can be stacked on top of each other without any uprights or structural elements.

It is no longer necessary to limit stack heights to man height.

Figure 1: High-density storage using a TRUNINGER magnet system

Your benefits

|

Fast and safe material handling

A correctly designed magnet system enables fast and safe access to the warehouse reception, storage and dispatch areas. By using a TRUNINGER magnet system you save not only space, but lots of time as well.

Magnets, when used properly, allow the load to be approached, picked, unloaded and transported to the storage location or processing area, quickly and reliably.

It is not possible to keep beams stable using a single crane hook. It is only when using two hooks that the magnets remain parallel to the material being lifted. Two hooks are thus a prerequisite for safe and efficient one-man operation!

Figure 2: Passive telescope used for transporting a layer of hollow sections

A simple and low-cost solution for cranes with two independent trolleys is to use two magnet groups that are suspended directly from the crane hooks and kept in line by a passive telescope (see figure 2).

Two hoists, each equipped with twin hooks, offer a particularly lightweight and flexible solution for long beams. The distance between the two independently controllable magnet groups can thus be adapted to different beam lengths. A V-rope tensioning mechanism eliminates sway.

Figure 3: Two individual spreader beams with anti-sway V-rope tensioning mechanism for lifting narrow beams

Your benefits

|

Figure 4: Cost-efficient compact storage of long hollow sections using a magnet system

Transporting layers of billets

Continuous production processes

TRUNINGER magnet systems are used not only in storage applications. They have also become indispensable for steel bar or wire rolling mills to feed the production process.

Such process may start with layers of hot billets up to 600°C being transported using special heat resistant magnets from TRUNINGER (see figure 1). A magnet system ensures that the semi-finished steel gets continuously and safely transported for storage or further processing.

Figure 1: Hot billets on a cooling bed lifted off in layers by the magnet system

The advantagesof using a magnetic system are very clear

| This results in major benefits

|

Figure 2: Densely stacked, warm billets being lifted in layers into the pusher furnace

TRUNINGER design features

TRUNINGER designs and manufactures special magnet systems for handling billets of all

commercial sizes.

- Robust spreader beams and strong magnets are key features of magnet grippers designed specifically for billets

- The magnet spreader beams needs to adapt to different billet length and layer width. Typical solutions are single magnets (see figure 2), spreader beams carrying multiple magnets adapting magnet distances to billet length (see figure 3)

- The magnet control system enables the magnets to be moved automatically and thus to be correctly positioned on the load. Load deflection can be minimises and safe transport be guaranteed

- A load slewing device allows the load to be rotated (see figure 3), thus enabling the billets to be aligned with the production flow or stackability to be improved (see figure 2)

- Automatic quick change between magnets for bundles and magnets for single billets

- Specially developed magnets with temperature-resistant coils guarantee a long service life under tough conditions

- Such magnets are also equipped with a heat shield protecting the magnets from hot load heat radiation

Figure 3: Magnet system with slewing device lifting-off a billet layer from a cooling bed