Repair

Fewer malfunctions–increased availability

When correctly operated and maintained, almost no malfunctions or defects occur on our magnet systems.

In case of failure, experts of TRUNINGER and our local partners are available to you competently and quickly.

Troubleshooting and repair services

We can provide support on-demand or based on a service contract.

Our specialists carry out the following specific tasks:

- Fault diagnosis (via telephone or on-site)

- Troubleshooting support

- On-site troubleshooting

- Delivery of replacement/spare parts

- Repair work on-site or in our factory

Spare parts

Available from stock

Efficient spare parts management plays a very important role in minimising magnet system downtime in the event of any malfunction. TRUNINGER’s spare parts service provides the following benefits:

- Immediate availability of all electrical SmartPick components out of stock.

- TRUNINGER magnet systems use lots of standard parts. One spare part on site can therefore be used for a number of different systems.

- All standardised spreader beam components are also available from stock.

- Guaranteed supply of spare parts for at least 10 years after the magnet system’s installation.

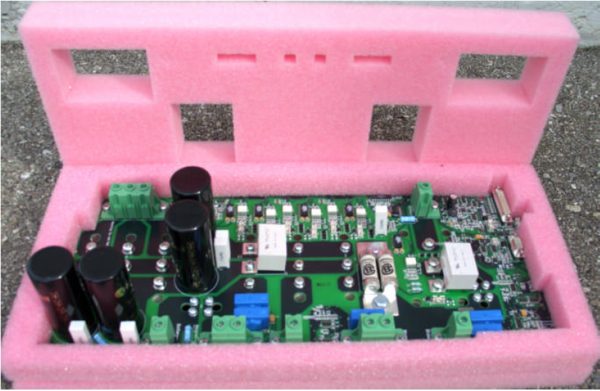

Our spare parts service is not only geared to rapid availability, but also committed to quality. We take care to ensure that all circuit boards and other sensitive electronic components reach the customer in perfect condition using special foam packaging (see figure 1).

Figure 1: PowerPick board in protective foam packaging

Wide in-house manufacturing range

TRUNINGER not only makes its own magnets, but produces and assembles the spreader beams in-house as well.

While mechanical parts are generally not available from stock, they can be made on request. Since a lot of the parts are manufactured in-house, we can produce many mechanical components very quickly.

Figure 2: Spreader beam components manufactured in-house